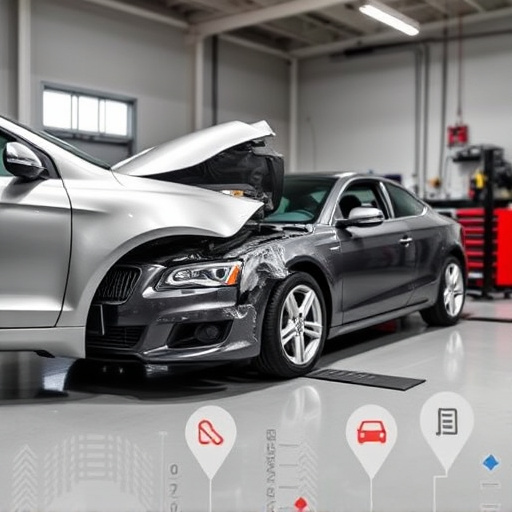

Paintless dent repair (PDR) techniques and specialized PDR tools for aluminum panels are transforming auto body services. These advanced tools offer efficient, cost-effective solutions for various damages, preserving vehicle aesthetics without traditional painting or sanding. Designed with temperature control and precise engineering, they streamline repairs, reduce downtime, and enhance productivity for collision centers, ultimately providing faster turnaround times while maintaining high-quality standards.

In the automotive repair landscape, Polymer Damage Repair (PDR) has emerged as a game-changer. When applied to aluminum panels, PDR offers a precise, efficient way to restore damaged vehicles to their original condition. This article delves into the world of specialized PDR tools designed exclusively for aluminum, exploring their key features and the myriad benefits they bring to auto body shops. From improved repair speed to enhanced finish quality, these tools are revolutionizing vehicle restoration.

- Understanding PDR and Its Application on Aluminum Panels

- Key Features of Specialized PDR Tools for Aluminum

- Benefits and Use Cases: Why These Tools are a Game-Changer

Understanding PDR and Its Application on Aluminum Panels

Paintless dent repair (PDR) is a specialized technique used to restore vehicle bodywork to its original condition without the need for traditional painting or sanding. This non-invasive method has gained significant popularity, especially in the auto repair industry, as it offers efficient and cost-effective solutions for various types of damage, including dents and scratches on vehicle surfaces. When applied to aluminum panels, PDR tools become indispensable assets for professional auto repair shops.

Aluminum, known for its lightweight and corrosion-resistant properties, presents unique challenges in vehicle bodywork. PDR techniques and tools are designed to cater to these specific needs, ensuring precise and effective repairs. By using specialized equipment, such as PDR hammers and pullers, trained technicians can carefully extract dents while preserving the integrity of the aluminum panel’s finish. This not only streamlines the vehicle repair services but also maintains the overall aesthetics of the auto repair shop’s work, making it a preferred choice for those seeking high-quality vehicle bodywork solutions without the lengthy downtime associated with traditional painting methods.

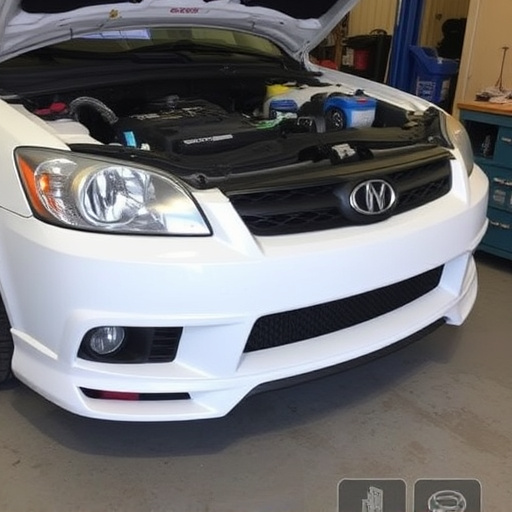

Key Features of Specialized PDR Tools for Aluminum

Specialized PDR tools designed for aluminum panels offer several key features that set them apart from general-purpose options. These include advanced materials and construction techniques, tailored to handle the unique properties of aluminum alloys. For instance, they often incorporate lightweight yet durable designs, ensuring minimal damage to the panel during repair processes. The use of precision engineering allows for precise manipulation, crucial when working with intricate aluminum designs found in modern vehicle bodies.

Furthermore, these specialized tools often come equipped with advanced features like temperature control and variable air pressure settings. This adaptability is essential for effective dent removal on aluminum without causing harmful heat buildup or leaving unsightly marks. Such tools are a boon for auto collision centers and body shop services, enhancing the efficiency of collision repair services while maintaining the aesthetic integrity of the vehicle’s aluminum components.

Benefits and Use Cases: Why These Tools are a Game-Changer

PDR tools designed specifically for aluminum panels are transforming the landscape of auto body services and vehicle body repair. These innovative solutions offer numerous benefits, making them a game-changer in the industry. One of the primary advantages is their efficiency; specialized PDR tools can quickly and accurately restore damaged aluminum surfaces, reducing repair times significantly. This is particularly beneficial for busy auto body work shops aiming to maximize productivity.

Moreover, these tools enhance precision and quality of repairs. Aluminum panels, known for their lightweight yet durable nature, require unique handling and techniques. PDR tools tailored for this material ensure that the original integrity and aesthetics of the panel are preserved. This level of expertise not only improves customer satisfaction but also reduces the need for costly re-painting or additional auto body work. By leveraging these specialized tools, repair shops can streamline their processes, offering faster turnaround times while maintaining high-quality standards in vehicle body repair.

PDR tools designed specifically for aluminum panels represent a significant advancement in the automotive repair industry. By leveraging specialized features tailored to the unique properties of aluminum, these tools offer enhanced precision, efficiency, and durability compared to traditional methods. The benefits are clear: faster repair times, reduced material waste, and improved overall quality. As the demand for lightweight and sustainable materials continues to grow, PDR tools optimized for aluminum will be indispensable, revolutionizing the way we approach panel repairs and setting a new standard in the market.