Paintless Dent Repair (PDR) is a leading, non-invasive auto body restoration technique that uses specialized PDR tools to fix minor dents and dings without traditional paint or panel replacement. These tools vary in size and type, from handheld devices for minor repairs to large industrial machines for complex jobs. Best practices for PDR include workspace preparation, selecting the right tool, applying even pressure, and regular maintenance of the tools to ensure optimal performance and minimize errors.

In today’s automotive industry, minimizing surface damage during panel repairs is paramount. Professional Detailing Restoration (PDR) tools have emerged as essential assets, revolutionizing the way we approach car panel repair. This article delves into the world of PDR technology, highlighting its significance in preserving vehicle aesthetics. We’ll explore key features and types of PDR tools that enable efficient repairs while minimizing damage to surface panels. Additionally, practical tips and best practices will guide professionals and enthusiasts alike in mastering PDR techniques.

- Understanding PDR and Its Importance for Minimal Surface Damage

- Key Features and Types of PDR Tools for Efficient Panel Repair

- Best Practices and Tips for Using PDR Tools to Prevent Surface Damage

Understanding PDR and Its Importance for Minimal Surface Damage

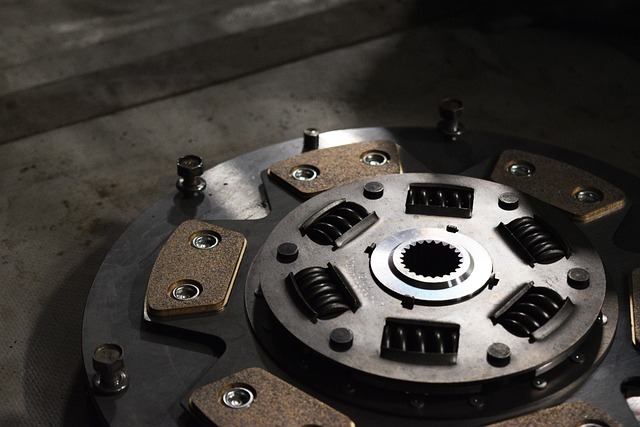

PDR, or Paintless Dent Repair, is a specialized technique within the auto repair industry designed to restore vehicle panels to their original state without the need for traditional car paint repair. This method has gained significant importance in collision repair centers, offering a faster and more cost-effective solution for minor dents and dings. By utilizing advanced PDR tools, technicians can effectively minimize surface damage, preserving the overall aesthetic of the vehicle.

In the realm of auto repair services, PDR plays a pivotal role in ensuring that vehicles maintain their value and appeal post-collision. Unlike conventional methods that often require extensive car paint repair or even complete panel replacement, PDR provides an efficient alternative. The use of specialized tools allows for precise manipulation of dented areas, making it ideal for addressing various types of damage, from minor fender benders to more complex panel deformities. This non-invasive approach not only saves time but also reduces the cost associated with traditional repair methods, making it a preferred choice for both collision repair centers and car owners alike.

Key Features and Types of PDR Tools for Efficient Panel Repair

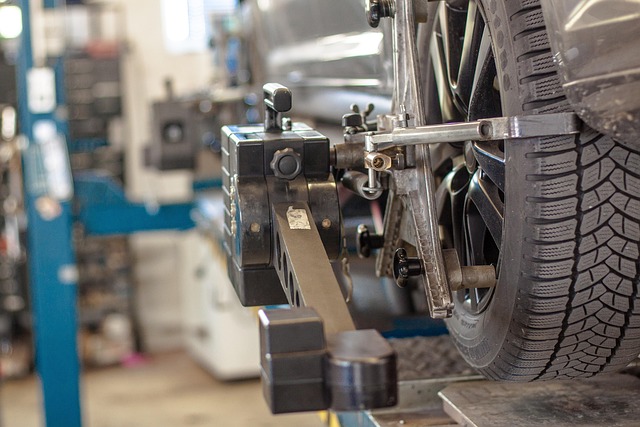

The effectiveness of PDR tools (Paintless Dent Repair) lies in their ability to minimize surface damage during panel repairs, making them a preferred choice for car scratch repair and car body repair. These tools are designed with various features that cater to different types and severity of dents, ensuring precise and efficient work. For instance, some models feature advanced technology like LED lights for better visibility and precision, while others come with customizable settings to adapt to specific collision center needs.

In terms of types, PDR tools can range from handheld devices suitable for minor repairs to large, industrial-grade machines for complex car body repair jobs. Handheld options offer manual control and agility, ideal for reaching tight spaces, whereas larger machines provide increased power and speed, making them more efficient in collision centers. Regardless of the type, modern PDR tools share a common goal: to restore vehicles to their pre-damage condition with minimal paint alteration or panel replacement.

Best Practices and Tips for Using PDR Tools to Prevent Surface Damage

When utilizing PDR tools for panel restoration, adopting best practices is paramount to prevent surface damage. Begin by preparing the work area thoroughly; ensure proper lighting and a clean environment to maximize visibility and reduce dust. Using the correct tool for the job is essential; match the PDR tool with the specific dent size and type. Apply gentle, even pressure during the process to avoid marring or scratching the panel’s surface. Maintain consistent contact between the tool and dent throughout the repair to achieve a seamless finish.

Regular maintenance and care of your PDR tools are also crucial. Keep them clean, well-lubricated, and stored properly when not in use. Calibrate and inspect them regularly to ensure optimal performance. Remember, patience is key; complex dents might require more time and attention. Practicing on similar panels before tackling actual collision repair jobs can significantly enhance your skills and minimize the risk of auto detailing or painting imperfections.

PDR (Paintless Dent Repair) tools have revolutionized panel repair, offering efficient solutions while minimizing surface damage. By understanding the importance of reducing dent impact and adopting best practices with these advanced tools, professionals can ensure superior repairs that preserve the aesthetics of vehicles. Investing in high-quality PDR equipment and adhering to expert tips will continue to drive success in this game-changing automotive restoration method.